Nova Energy-Nova Battery Company Profile

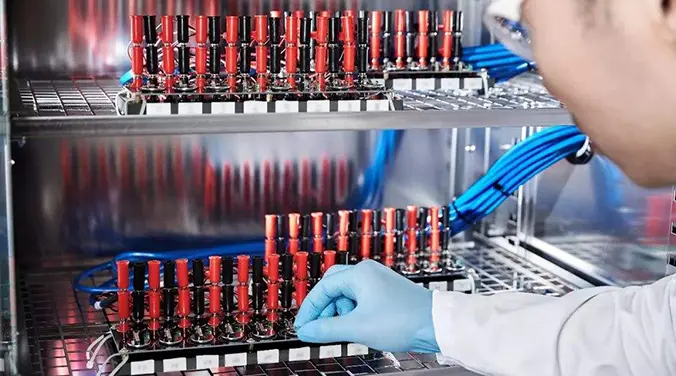

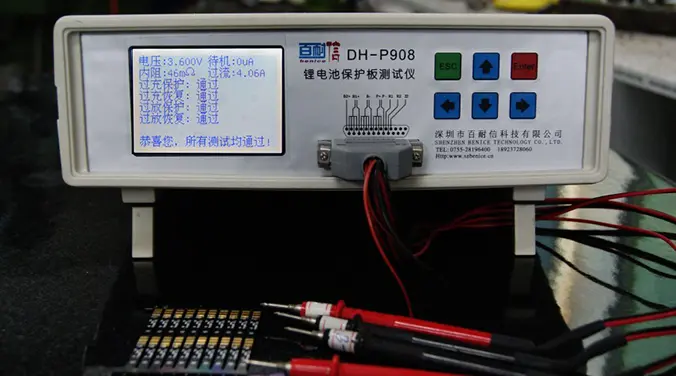

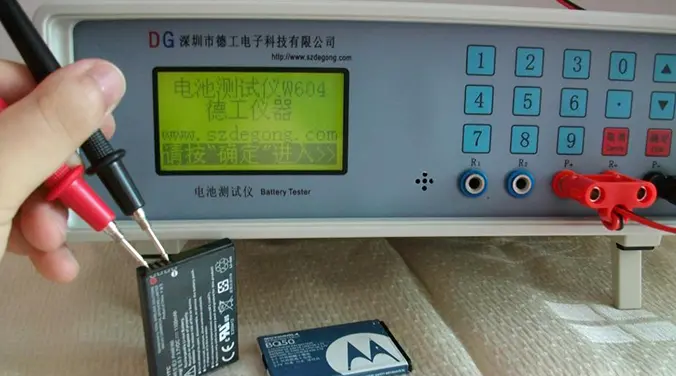

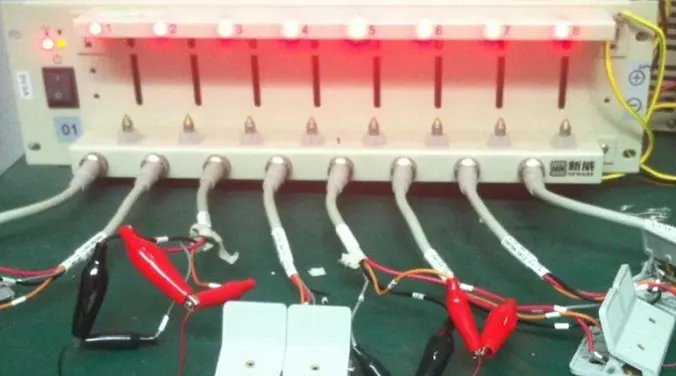

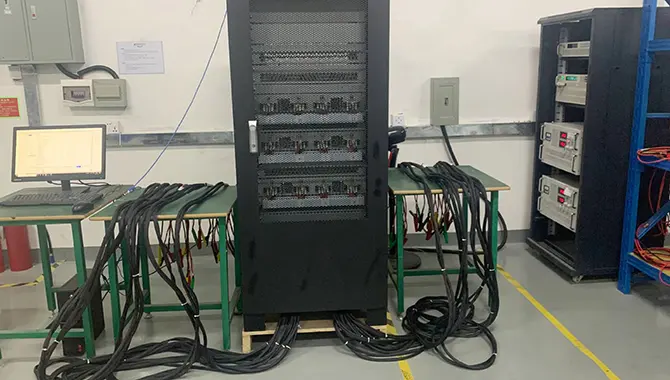

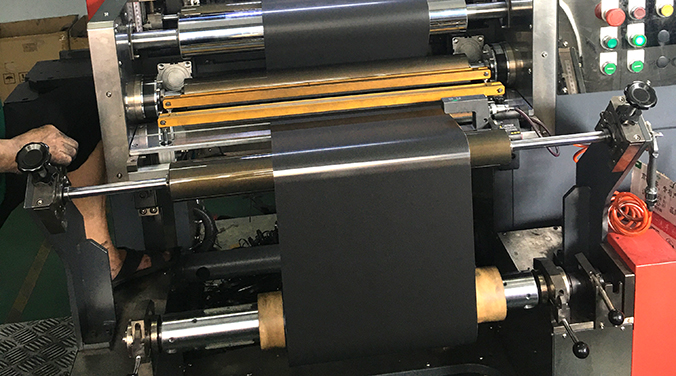

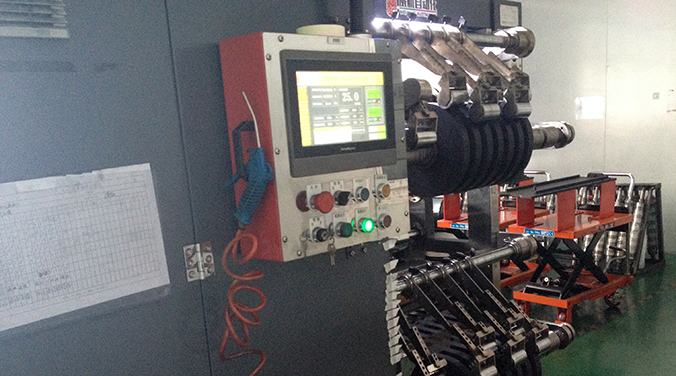

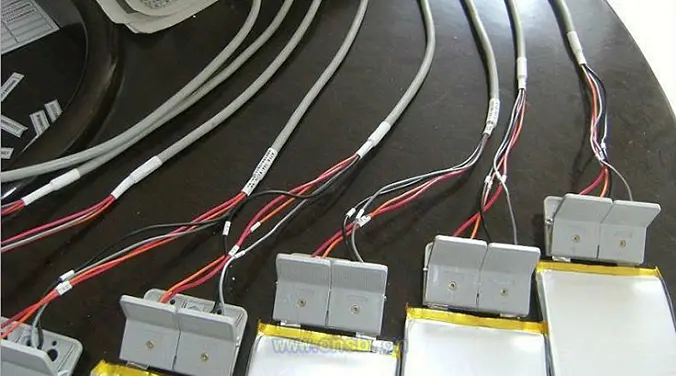

Shenzhen Nova Energy Co.,Ltd., is specialized in R&D, production and sales of Li-ion Polymer Battery, Li-ion Battery, LiFePO4 Battery, Solar storage battery, EV Battery and related Battery Solutions, after decades of dedicated research and development in the renewable energy sector since 2007, Shenzhen Nova Energy Co.,Ltd. boasts state-of-the-art factories spanning over 30,000 square meters of production area, staffed by a workforce of over 600 skilled individuals, including 60 senior engineers. Our commitment to excellence is underscored by the implementation of Total Quality Management and adherence to the ISO9001 quality management system. Presently, Novacell stands as a leading provider of comprehensive, tailored power solutions, offering rapid mass production and OEM/ODM services.

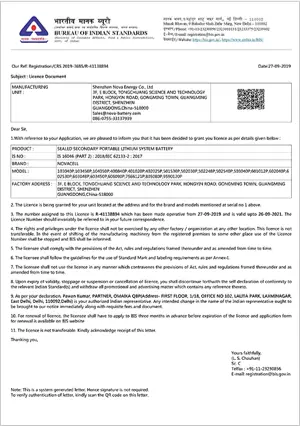

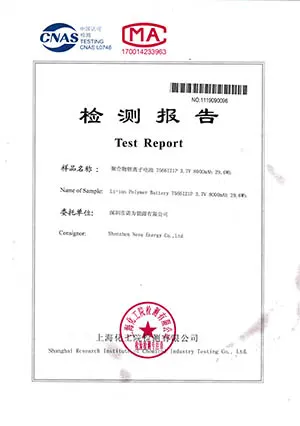

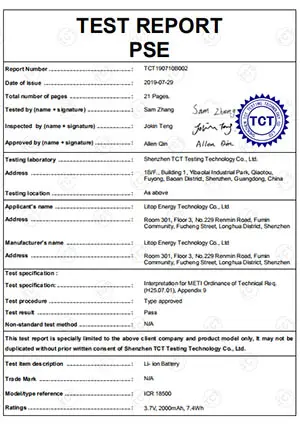

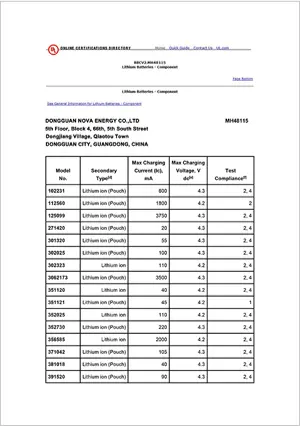

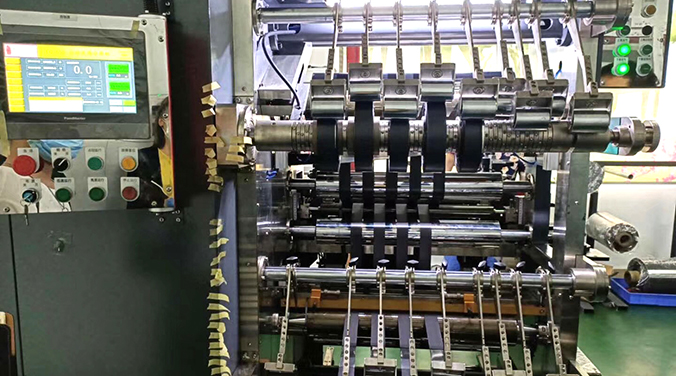

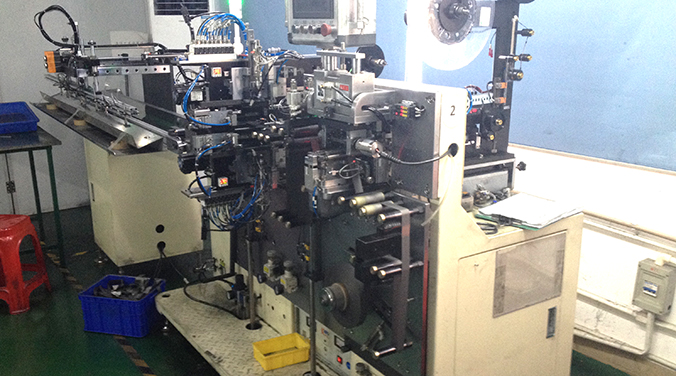

Utilizing cutting-edge automated machinery, we have significantly enhanced our production capabilities, achieving an annual output of 40GWH digital batteries, energy storage battery and electric battery. The majority of our products are internationally patented and hold certifications, including CE, RoHS, IEC62133, BIS, KC, PSE, CB, UL, UN38.3, and MSDS, ensuring compliance with rigorous quality and safety standards.

Our company spirit embodies "Sincere cooperation, Bravery in innovation, and Strive for excellence". Guided by a management philosophy of being "Market-oriented, customer-focused, and Talent-based", we are committed to fulfilling our mission of providing people with reliable and sustainable green energy that surpasses customer expectations. Our core values, "Customer satisfaction, Technology innovation, and Society advancement", drive our actions. At Nova, we dedicate ourselves to innovative and intelligent green energy solutions